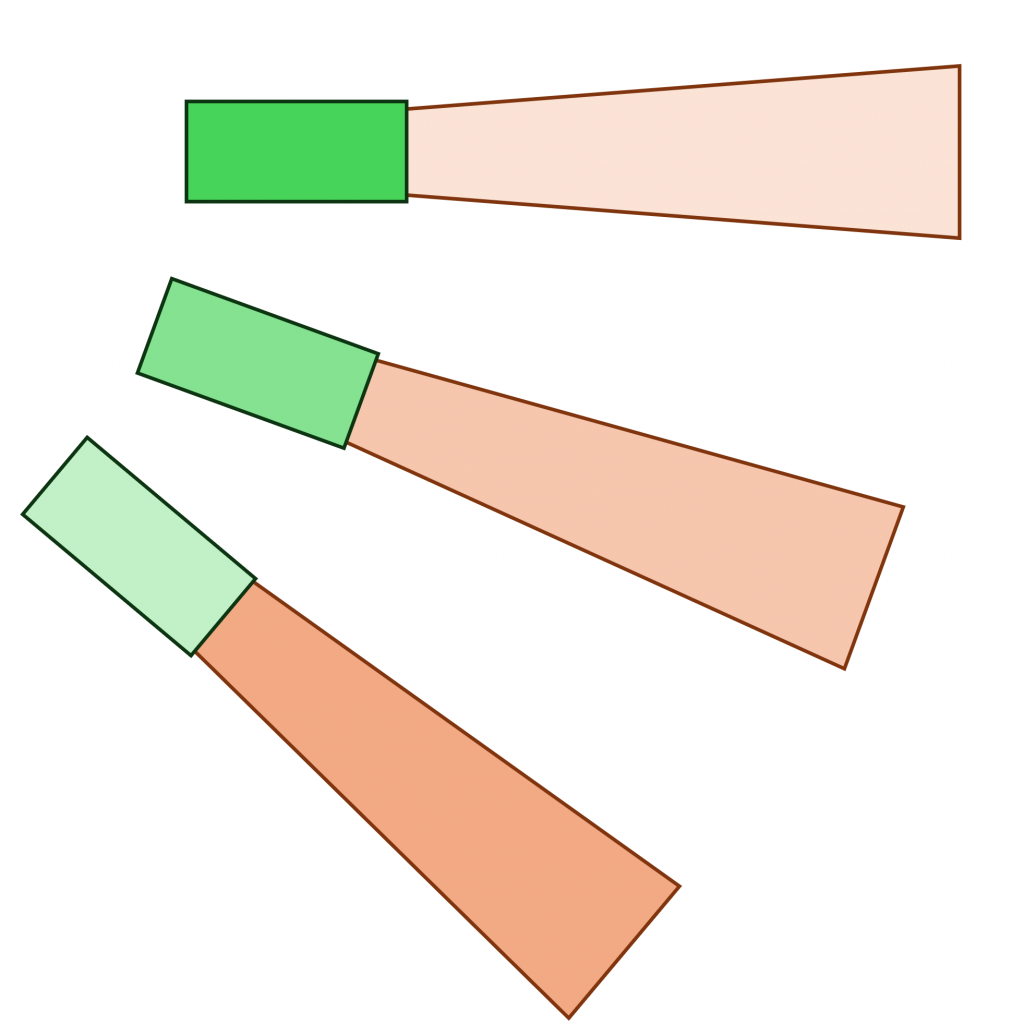

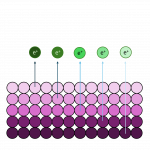

The inelastic mean free path, or IMFP (λ), is defined as the average distance an electron with a given energy travels through a solid before losing energy by inelastic collision. Approximately 68 % of all photoelectrons will come from within a depth of λ, whereas the majority (99.7 %) of photoelectrons will come from a depth of 3λ. For most core electrons excited by Al Kα X-rays, this depth is a few nanometers (nm). Elements or compounds with a greater density will have shallower IMFPs as will core electrons with higher binding energies (i.e. lower kinetic energies). By application of the equations defined in references [1,2] the IMFP can be used to calculate the thickness of oxide films and thin overlayers. Tilting the sample with respect to the analyzer (Angle Resolved XPS) one can reduce the effective IMFP, and it is useful for gaining an understanding of thin surface layers. Such analysis can also be achieved using synchrotron radiation through changing the incident photon energy. Many great tools exist to help you determine and calculate IMFPs, some of which may be found below:

Analysis Depth in XPS & IMFP

XPS owes it’s status as a surface sensitive technique to the processes of inelastic collision when an electron travels through matter. The likelihood of the collisions occurring scales with depth into a surface, and as such the majority of a signal from an XPS experiment arises from the atoms at the surface.

“Information depth” refers to the effective depth within a material from which photoelectrons can escape and be detected, thereby contributing to the measured spectrum. This depth is determined by the inelastic mean free path (IMFP) of the photoelectrons. The information depth DD is often approximated as three times the IMFP (λ), which provides a practical estimate of the depth from which 95% of the detected electrons originate: D≈3λ This approximation accounts for the exponential attenuation of the photoelectron signal with depth, providing a measure of the depth sensitivity of the PES technique.

- T.A. Carlson, G.E. McGuire, Study of the x-ray photoelectron spectrum of tungsten—tungsten oxide as a function of thickness of the surface oxide layer, J. Electron Spectrosc. Relat. Phenom. 1 (1972/73) 161. https://doi.org/10.1016/0368-2048(72)80029-X

- B.R. Strohmeier, An ESCA method for determining the oxide thickness on aluminum alloys, Surf. Interface Anal. 15 (1990) 51. https://doi.org/10.1002/sia.740150109